Which crankshaft grinding wheel is best for your budget

For buyers who want to save money, aluminum oxide is the best crankshaft grinding wheel material. This choice works well and does not cost much. Many people say aluminum oxide lasts longer than other simple types. They often say it works like a cylindrical grinding wheel because it is efficient. Picking the right crankshaft grinding wheel means you must think about both the first price and how long it will last.

Key Takeaways

Aluminum oxide wheels are not expensive and last a long time. They work well for grinding softer metals like cast iron and mild steel. These wheels are a good choice if you want to save money.

Cbn and diamond wheels work best on hard metals and last the longest. They cost more at first, but they help you finish jobs faster. You also spend less time fixing or changing them.

Picking the right grinding wheel depends on your budget and what metal you grind. Your machine’s power also matters for getting good results and saving money.

Taking care of your wheels, like cleaning and dressing them often, makes them last longer. Clean machines and good care help you get better grinding and save money.

Buying from experts and using smart features like segmented wheels and coolant slots can help you spend less. These tips also make grinding work better and faster.

Crankshaft Grinding Wheel Materials

Picking the best crankshaft grinding wheel is not easy. You need to think about a few things. Look at the abrasive type and if it works with your part. Check the wheel size and what it is made of. The kind of grinding machine matters too. It is good to know if the wheel is easy to take care of. Some people also look at the brand’s reputation. If you want to save money, you will care about price, how long it lasts, and how well it works.

Below is a table that shows how each grinding wheel material compares. It lists cost, durability, performance, and what they are used for:

Grinding Wheel Type | Cost | Durability | Performance Characteristics | Typical Applications |

|---|---|---|---|---|

Aluminum Oxide | Low | Moderate; robust and fracture resistant | General purpose grinding on ferrous metals; moderate performance; widely used | Carbon steel, alloy steel, high-speed steel, wrought iron, bronzes |

Silicon Carbide | Low to moderate | Less durable; brittle and wears faster | Sharper and harder than aluminum oxide; mainly for non-ferrous materials; less durable | Grey iron, chilled iron, brass, soft bronze, aluminum, stone, rubber |

Diamond | High | Extended lifespan; excellent form retention | Superior efficiency; ideal for hard, fragile materials; excellent abrasion and heat resistance | Hard alloys, glass, ceramics, valuable stones |

cbn | High | Very high; indefinite lifespan; excellent thermal conductivity | Better suited for hard ferrous metals; outperforms diamond in these applications; fine grinding; does not burn tools | Hardened steel, cast iron camshaft, crankshaft, gear shaft |

Vitrified Bond | Moderate | Good mechanical strength; brittle; heat resistant | Strong bond; good shape retention; requires careful handling; cool cutting on heat sensitive materials | Steel, bearing, fabrication, precision grinding industries |

Resin Bond | Low to moderate | Lower life than vitrified; flexible; vibration-free | Flexible bond; used for rough grinding and cut-off; generally lower cost but shorter life | Rough grinding, cut-off operations |

Aluminum Oxide Wheel

Aluminum oxide wheels do not cost much. They last a fair amount of time and are tough. People use them for many jobs on ferrous metals. These wheels work with carbon steel, alloy steel, and bronzes. They are popular because they are cheap and can be used for many things.

Silicon Carbide Wheels

Silicon carbide wheels are a bit more expensive than aluminum oxide. They are sharper and harder but break more easily. They wear out faster. These wheels are best for non-ferrous materials like grey iron, brass, and aluminum. They can keep working well because they clean themselves as they grind.

Diamond Wheels

Diamond wheels cost the most and last the longest. They are great for jobs that need a very hard grinding wheel. They resist wear and heat very well. Diamond is much harder than silicon carbide. It also moves heat away better. These wheels are good for hard alloys, glass, and ceramics. They work well for jobs that need careful grinding.

cbn Wheels

cbn wheels are almost as hard as diamond. They can handle very high heat, up to 2500°F. They move heat away fast. cbn wheels are better than diamond for grinding hard ferrous metals. People use different types of cbn wheels for different jobs. Vitrified bond cbn wheels work fast and last a long time. Electroplated and metal bond cbn wheels cut sharply and help parts last longer. Resin bond cbn wheels are good for rough grinding and cutting off pieces.

Vitrified Bond Wheel

Vitrified bond wheels mix ceramic bonds with abrasives. They are strong, resist heat, and keep their shape. These wheels are used in steel, bearing, and making parts. People use vitrified bond cbn wheels for careful and cool grinding when heat is a problem.

Resin Bond Wheels

Resin bond wheels are cheaper and make grinding smooth. They do not last as long as vitrified wheels but are flexible. Resin bond cbn wheels are used for rough grinding and cutting off. These wheels help people get good results without spending a lot.

Pros and Cons by Material

Aluminum Oxide Wheel

Aluminum oxide wheels are a good choice for many jobs. They are tough and hard enough for soft and hard metals. When used with vitrified bonds, they work well and handle heat. Many companies use aluminum oxide wheels for careful grinding. These wheels last a long time and give steady results. Some special wheels, like the 3M vitrified grinding wheel 33VX, last up to 20% longer than regular ones. This happens because they have stronger bonds and better materials. Ceramic and vitrified bonded wheels with aluminum oxide are popular in car factories. They last longer and are very strong. But aluminum oxide wheels do not last as long or work as well as cbn or diamond wheels in tough jobs.

Tip: Aluminum oxide wheels are best for general grinding. They balance cost and how long they last.

Pros:

Good price for most people

Works for many different jobs

Great for careful grinding

Lasts a fair amount of time with strong bonds

Cons:

Not great for removing lots of material

Needs to be replaced more often in tough jobs

Silicon Carbide Wheels

Silicon carbide wheels are cheap for many users. They are sharper and harder than aluminum oxide wheels. They work well for grinding non-ferrous metals. But they wear out faster and need to be fixed more often. Silicon carbide wheels get hotter when used. This can make grinding less accurate and change the finish.

Aspect | Details for Silicon Carbide Crankshaft Grinding Wheels (Budget Buyers) |

|---|---|

Pros | - Cheap and easy to buy |

Cons | - Wears out quickly |

Note: Silicon carbide wheels are best for rough and semi-finish grinding on non-ferrous metals.

Diamond Wheels

Diamond wheels work very well for grinding hard and breakable things. They are very efficient and resist wearing down. In expensive jobs, diamond wheels usually cost less than cbn wheels. But diamond wheels cannot handle as much heat. They work up to 800 °C, while cbn wheels can go up to 1350 °C. Diamond wheels are great for jobs that need a smooth finish on ceramics, glass, and carbide. They do not work for ferrous metals because diamond reacts with iron when hot.

Pros:

Very hard to wear out and lasts long

Makes surfaces very smooth

Costs less to use than cbn wheels

Best for hard and breakable materials

Cons:

Not good for ferrous metals

Handles less heat than cbn wheels

Costs more at first than simple wheels

CBN Wheels

cbn wheels are the best for very accurate grinding, especially on hard ferrous metals like crankshafts. They last much longer than ceramic corundum wheels. cbn wheels keep their shape and cut the same way every time. They make less heat, so parts do not burn and wheels last longer. cbn wheels help work get done about 30% faster. There are different types for different jobs and budgets, like vitrified, resin, hybrid, metal, electroplated, and vacuum brazed.

Vitrified bond cbn wheels are good for careful grinding, last long, and do not cost too much. They resist wearing down and keep their size, so they are great for careful jobs.

Resin bond cbn wheels bend and make a nice finish but do not last as long in hard jobs.

Hybrid and metal bond cbn wheels work fast and last long but need special machines.

Electroplated and vacuum brazed cbn wheels cut fast and remove lots of material but cannot be fixed and must be changed when worn out.

💡 cbn wheels last longer, grind more accurately, and work best for crankshaft grinding.

Pros:

Lasts a very long time

Grinds very accurately

Works fast and needs less fixing

Good for many jobs, especially hard ferrous metals

Cons:

Costs more at first, especially for special types

Some need special machines and care

Not always the best choice for small or simple jobs

Vitrified Bond Wheel

Vitrified bond wheels are stiff and keep their shape well. Their ceramic bond stops bending, which helps keep tight sizes in crankshaft grinding. These wheels wear down slowly, handle heat well, and let coolant move through tiny holes. Vitrified wheels can be fixed to keep their shape and last longer. They are better than resin bond wheels for big jobs that need careful grinding.

Feature | Vitrified Bond Wheels | Resin Bond Wheels |

|---|---|---|

Bond Strength | Strong bond, holds grains tightly | Weaker bond |

Form Retention | Keeps shape better, easy to fix | Loses shape more easily |

Stiffness | Very stiff, does not bend much | More bendy, gives under pressure |

Heat Resistance | Handles heat well | Handles less heat |

Porosity | Tiny holes help cool | Fewer holes, less cooling |

Precision | Easier to keep tight sizes | Harder to keep tight sizes |

Wheel Life | Lasts longer, needs fewer changes | Shorter life, needs more changes |

Cost-effectiveness | Saves money because it lasts and works well | Costs more for careful jobs |

Tip: Vitrified bond wheels are best for careful grinding and big jobs in car factories.

Resin Bond Wheels

Resin bond wheels bend and are strong, so they are good for smooth finishes and flexible jobs. They cost less and make surfaces smooth, but do not last as long or handle heat as well as vitrified bond wheels. Resin bond wheels bend under pressure, so it is harder to keep tight sizes. Some special resin bond wheels, like Asahi's Bright Star, can make very smooth finishes on hard things. Most resin bond wheels need to be changed more often and do not last as long or work as well as vitrified wheels.

Pros:

Costs less and bends easily

Good for smooth finishes

Works for many different jobs

Cons:

Does not last as long or handle heat well

Not great for careful or big jobs

Needs to be changed more often

Note: Resin bond wheels are best for rough grinding, cutting off, and jobs where bending and smooth finishes matter more than lasting a long time.

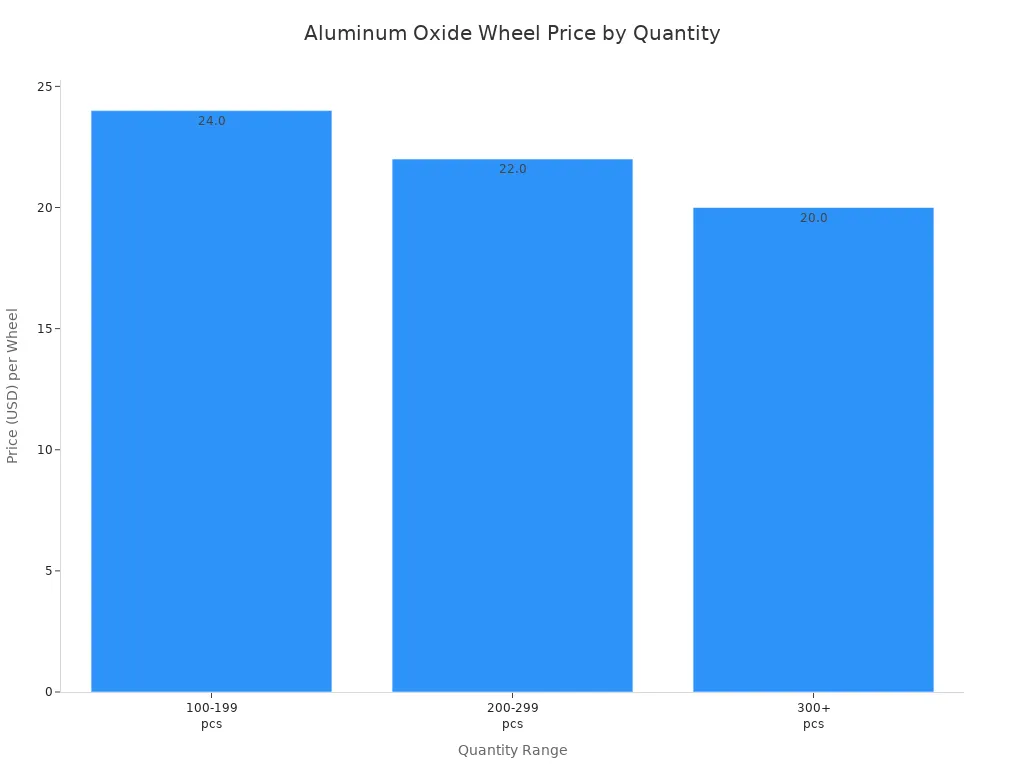

Matching to Your Budget

Low Budget

People who do not want to spend much often pick aluminum oxide wheels. These wheels are cheap and work well for many jobs. Aluminum oxide is good for taking off a little or a medium amount of metal. It is also good for finishing or roughing crankshafts that are not very hard, with a Rockwell hardness of 35Rc or less. The table below shows how these choices stack up:

Grinding Wheel Grade | Abrasive Material | Recommended Use Case | Hardness Suitability (Rockwell) | Budget Friendliness |

|---|---|---|---|---|

Superior Grade | Aluminum-Oxide | Light to medium stock removal, finishing or roughing | 35Rc or less | More budget-friendly option |

Premium Grade | Salt-and-pepper friable abrasive | Harder materials, faster and cooler grinding | 35Rc or more | Higher performance, likely more expensive |

Aluminum oxide wheels cost less than cbn or diamond wheels. They last a good amount of time and make a nice finish for most jobs. Shops can save more money by taking care of their wheels and using grinders that do not use too much power. Buying used CNC grinders also helps small shops spend less.

Tip: If you dress and clean your wheel often, it will last longer and work better.

Mid-Range

If you have a bit more money, you can pick from more options. Many shops use cbn wheels for crankshafts made of hard steel because they are very exact and last long. Aluminum oxide wheels are still a good pick for crankshafts made of cast iron. Some Chinese CNC crankshaft grinders can use both types of wheels. These machines are a good deal for many jobs. They often have features like automatic oiling and special coatings that help the wheels last longer and make a better finish.

Cbn wheels last longer and are more exact than simple wheels.

Aluminum oxide wheels still work for easier jobs.

Machines with automatic features help keep the finish even and save work.

For people with a mid-range budget, using both cbn and aluminum oxide wheels with the right machine helps save money and get good results.

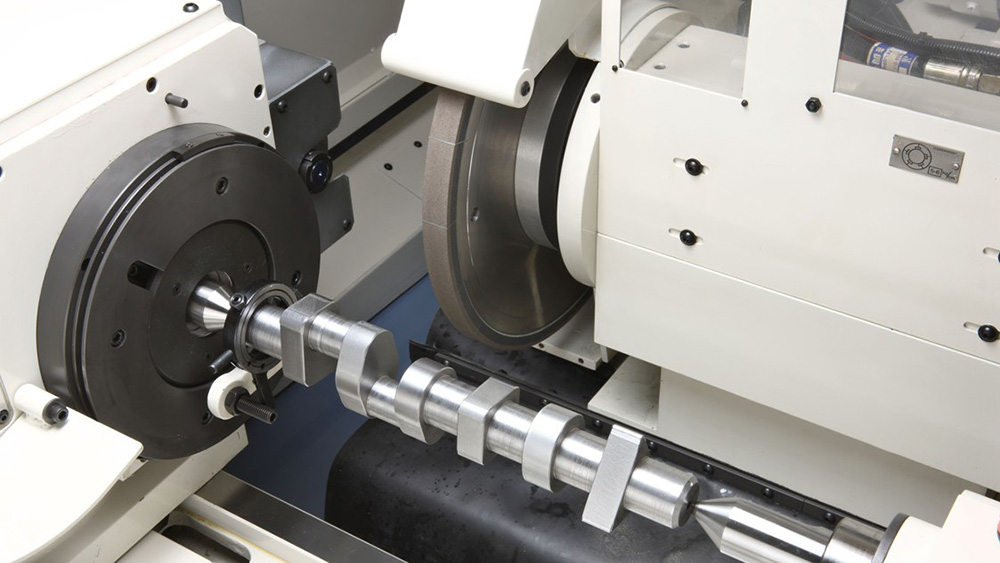

High-End

If you can spend a lot, you want the best results and the most exact work. Vitrified cbn wheels are the top choice for tough car jobs. These wheels use strong cores made from high-tensile steel or carbon fiber. This makes them last longer and not change shape from heat. Vitrified cbn wheels do not need to be dressed often, keep their shape, and make the surface look the same every time. They also stop the crankshaft from getting too hot or damaged.

Superabrasives like cbn and diamond last a very long time and are very exact.

Special bonds mean you do not have to dress the wheel as much and it keeps its shape.

Expensive wheels are worth it because they make a smoother finish, keep tight sizes, and help big shops work faster with less stopping.

People who spend more get the best cbn wheels. These wheels last the longest, are the most exact, and make the best finish for hard jobs.

Cost vs. Performance

When to Spend More

Picking the best crankshaft grinding wheel means thinking about both price and how well it works. Sometimes, paying more at first gives better results later. Vitrified CBN wheels work really well on hard-to-grind materials like Inconel, soft stainless steels, and tough steels such as 52100 and D2. These wheels are great for jobs that need to remove a lot of material and for shafts with many sizes, like those in car transmissions and cutting tools.

Workers notice that these wheels help finish jobs faster and need fewer changes. Newer wheels let you do peel grinding, which makes a smoother finish and keeps things accurate. Grinding many sizes at once saves money on tools and cuts down on setup time. Machines that are very stiff, run wheels at 90-140 m/sec, and have good wheel care systems help get the most from these costly wheels. Using water-based coolants helps cool things down and lets you work faster, which helps balance out the cost of expensive wheels in tough jobs.

Spending more on better wheels and machines is smart when you need top accuracy, want to work faster, and save money over time.

Long-Term Value

Long-term value means looking at more than just the starting price. You should also think about how long the wheel lasts and how well it works. Shops that buy top wheels for hard jobs change wheels less, stop less, and keep better control over sizes. These wheels stay accurate for many uses, so there is less waste and work goes smoother.

A table below shows what matters for long-term value in different wheels:

Factor | Low-Cost Wheels | Premium Wheels |

|---|---|---|

Initial Cost | Low | High |

Wheel Life | Shorter | Longer |

Precision Retention | Moderate | Excellent |

Downtime | More frequent | Less frequent |

Surface Finish | Acceptable | Superior |

Productivity | Lower | Higher |

Shops that use high-end wheels for tough grinding get the most for their money. They get smoother finishes, tighter sizes, and can do more work. Over time, saving on repairs and making more parts makes the higher price worth it.

Money-Saving Tips

Buying Advice

Picking the right crankshaft grinding wheel helps shops save money. You do not have to lose quality. Many experts like the Engineered Segment System. This system lets you change only the broken abrasive segments. You do not need to buy a whole new wheel. Shops can use the same wheel hub again. This lowers costs and makes downtime shorter. The system lets you design each wheel for the exact job. This means less waste and helps the environment.

When buying, pick suppliers who know a lot about abrasives. Good suppliers help you choose the right wheel for your crankshaft. This makes the wheel last longer and work better. Slotting the grinding wheel is also smart. Slots help coolant move better. This stops burning and makes grinding faster. This works well for high-performance and diesel crankshafts.

Tip: Always look at how much a supplier knows, not just the price. Good advice helps wheels last longer and gives better results.

Maintenance

Taking care of grinding wheels helps them last longer. This saves money over time. Shops should keep dressing diamonds sharp. Turn them often. This keeps cutting strong and makes surfaces smooth. Keep the crankshaft grinder in good shape. This protects your investment and helps work stay steady.

A simple checklist for maintenance:

Check the wheel for cracks or wear before using.

Dress the wheel often to keep its shape and cutting power.

Clean the machine and work area to stop debris from building up.

Watch coolant flow to stop overheating and help the wheel last longer.

A wheel that is well cared for lasts longer and works better. Shops that do these things have less downtime and get more value from each wheel they buy.

Picking the right crankshaft grinding wheel depends on your money and job. The table below shows which wheel is best for each budget:

Budget Category | Recommended Grinding Wheel Material | Suitable Crankshaft Material | Machine Capability and Notes |

|---|---|---|---|

High-End | CBN and Diamond | Hardened and superhard steel | Advanced CNC grinders use these wheels. They give better accuracy, work faster, and last longer. |

Mid-Range | CBN | Hardened steel | These wheels cost less and work well. They fit machines that use CBN and give good results. |

Budget-Friendly | Aluminum Oxide | Cast iron | These wheels work with cheaper machines. They do not fit all jobs but are fine for cast iron shafts. |

Buyers should look at the first price and how much they save later. They need to pick a wheel that matches their job and machine. For the best outcome, they should think about what they want to grind and ask experts for advice.

Tip: Keeping wheels clean and in good shape helps them last longer and makes grinding better.

FAQ

What is the most affordable crankshaft grinding wheel material?

Aluminum oxide costs the least for most people. It works well for basic grinding jobs. Many shops pick it to save money and still get good results.

How often should a grinding wheel be replaced?

How often you change wheels depends on use and material. Shops swap wheels when they stop working well or look worn out. Checking wheels often helps avoid surprise problems and keeps grinding steady.

Can one grinding wheel work for all crankshaft materials?

No single wheel fits every crankshaft material. Aluminum oxide is good for cast iron and softer steels. CBN and diamond wheels are better for hard or special alloys. Picking the right wheel helps work go faster and look better.

Do expensive wheels save money in the long run?

High-end wheels like CBN and diamond last longer and cut downtime. They help shops get smoother finishes and tighter sizes. Buying top wheels usually means spending less over time.

What maintenance extends grinding wheel life?

Shops should dress wheels often, look for cracks, and clean machines after each job. Good coolant flow stops overheating. These steps help wheels last longer and work better.